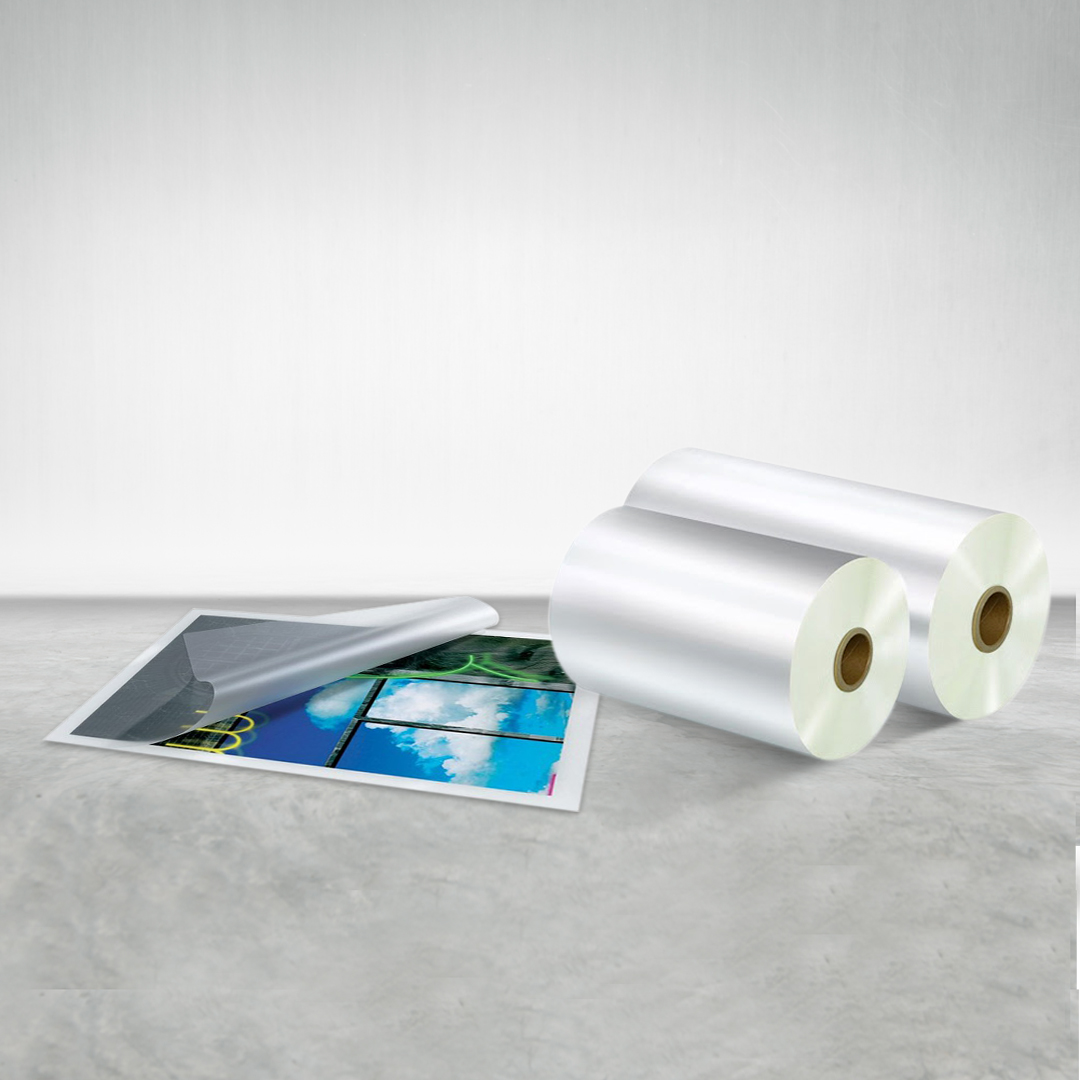

Thermal Film

- Providing a beautiful appearance to the product

- A barrier against product loss and scratching

- Suitable adhesion on surfaces

- Appropriate flexibility

Description

Plastic Machine Alvan Thermal film

In the offset printing industry, cellophane stretching is the first step after printing and before the paper-cutting operation, during which thermal film or thermal cellophane is stretched on the printed product with the help of heat and using cellophane stretching devices.

Thermal film actually acts as a protective layer, and in addition to the transparency and beauty of the printed word, it protects it against the penetration of moisture, pollution, scratches, etc., and also significantly increases the durability of the print and color. For this reason, thermal film is used for all kinds of printed items, including books, magazines, packaging boxes, labels, etc. Plastic Machine Alvan uses BOPP raw materials and glue to produce thermal film.

Features of BOPP-based thermal film

BOPP-based thermal film is a versatile and cost-effective solution for protecting and enhancing offset printing materials. Thermal film keeps its shape well and resists temperature changes and shrinking. This film improves the durability of the print compound and ensures a strong and durable bond. Other features of this product include the following:

- Excellent quality: The transparent sample of thermal film provides high clarity, increases the visual quality of laminated materials, and has a beautiful effect on your product and packaging.

- Durable Protection: This film protects laminated items from scratches, moisture, and tears, extending their lifespan.

- Various types: Thermal film is available in glossy, matte, velvety, etc., allowing you to choose the film that best matches the final product.

- Ease of use: The thermal film lamination process requires only heat and pressure, making it suitable for professional use.

- Environmentally Friendly: Thermal film is recyclable and does not contain harmful solvents or adhesives.

- Suitable for high-speed printing: thermal cellophane works well with various printing techniques, including offset. This Alvan machine plastic product can be applied to printing works at a very high speed, which increases the final speed and productivity of your production line.

Applications of thermal cellophane

As mentioned earlier, adding a layer of thermal film to printed works is the first step after offset printing because, without that, other post-printing steps, such as UV (glossy), gilding, etc., cannot be done.

The thermal film is applied to a wide range of printed items such as documents, business cards, photos, postcards, book covers, identification cards, etc. In addition to the beauty and preservation of the structure, making the printed work resistant also helps to increase its useful life.

Types of thermal cellophane

Thermal film is available in different types of glossy, matte, velvet, and metalized thermal film, and each one has its use. Nevertheless, the use of two kinds of shiny and matte in printing projects is more common, and Plastic Machine Alvan Company is one of the largest producers in Iran.

Glossy thermal film is the most common type and is used for laminating and wrapping a wide variety of products. The transparency of this type of film is very high. It gives a clean and professional appearance to the final packaging. The use of glossy cellophane on printed products makes the colors more vivid and prominent. This type of wrap film adds more polish by reflecting light from the printed surface and increases its visual beauty. Note that light reflection from a glossy surface can be very high. Therefore, if the printed product is to be used in environments with direct light, it is better not to use glossy film.

How to order thermal film

Plastic Machine Alvan company is proud to offer a wide range of high-quality products to its valued customers, and it is the leading producer of thermal film in the Iranian market. The thermal film produced by Plastic Machine Alvan is made in two types, transparent and opaque, with international standard widths of 22.5 to 99.5 cm and a standard length of 3000 meters. It is possible to produce thermal film in customized lengths and widths according to the request of our dear customers.

The thermal film is produced using high-quality raw materials and the knowledge and experience of experienced personnel, and it is suitable for various packaging purposes. To get more information and inquire about the price of thermal cellophane, you can contact the numbers listed on the site.